Industrial Vee belts are a cornerstone of power transmission systems in numerous industries, from manufacturing to agriculture. These belts offer a balance of durability, efficiency, and cost-effectiveness, making them an essential component in machinery that requires reliable power transfer. In this blog post, we will examine why industrial Vee belts remain a popular choice for industrial applications and how they contribute to the performance and longevity of machinery.

1. Optimized Power Transmission and Load Distribution

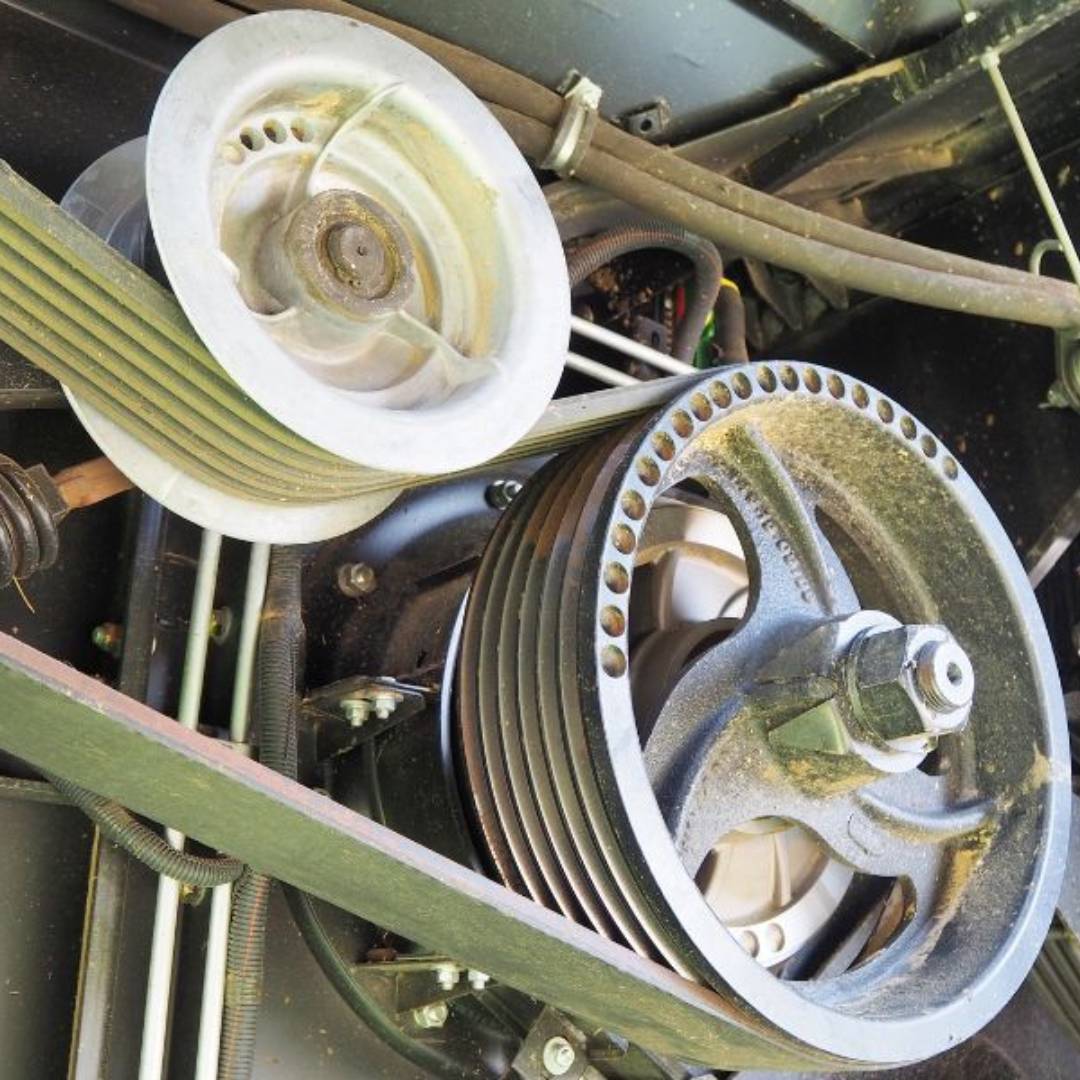

The V-shaped design of industrial Vee belts ensures optimal grip in pulley systems, allowing for superior power transmission. The shape of the belt creates a wedging action, increasing friction and reducing the chance of slippage, even under high torque or heavy load conditions. This means that Vee belts can handle the rigorous demands of industrial machinery with high precision and efficiency.

This feature is especially beneficial in industries such as mining, automotive, and construction, where equipment must perform under extreme conditions. Vee belts ensure consistent, smooth power transfer, preventing operational delays and equipment breakdowns.

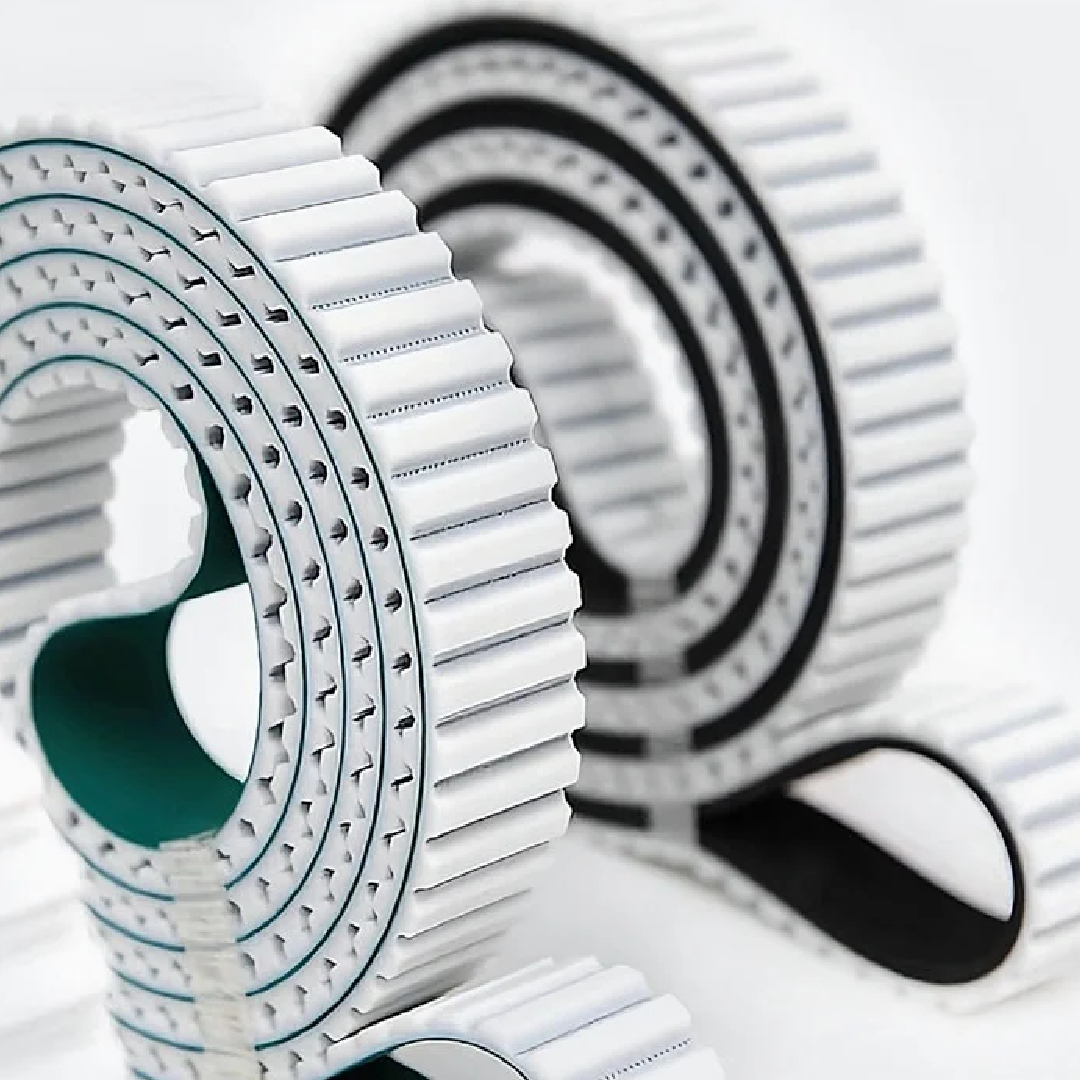

2. Highly Durable and Resistant to Wear

Industrial Vee belts are designed to last. Made from robust, heat-resistant rubber reinforced with synthetic fibers, these belts are built to withstand harsh environments. They can endure high temperatures, exposure to oil and chemicals, and the wear-and-tear that comes with heavy-duty applications, all while maintaining their integrity.

For industries like oil and gas, agriculture, and food processing, where machinery runs continuously, durable Vee belts mean fewer belt replacements, reduced downtime, and lower maintenance costs. Their ability to resist stretching and cracking ensures they perform effectively over long periods.

3. Cost-Effective and Low Maintenance

One of the major advantages of industrial Vee belts is their cost-effectiveness. Compared to more complex power transmission systems like chains or gears, Vee belts are relatively inexpensive and require minimal maintenance. With proper tensioning and alignment, these belts can operate for extended periods without the need for constant monitoring or frequent repairs.

For maintenance teams, this translates to lower operational costs and less downtime for equipment. Industrial Vee belts do not require lubrication and can run quietly and efficiently, further reducing the overall cost of ownership.

4. Versatility Across a Range of Applications

The versatility of industrial Vee belts is unmatched. These belts can be found in a wide array of applications, from factory conveyors and air compressors to agricultural machinery and pumps. Their ability to transmit power reliably across different mechanical setups makes them a go-to solution for industries that require consistent performance.

In agriculture, Vee belts are essential for powering equipment like threshers, irrigation systems, and tractors, while in industrial manufacturing, they are used to drive conveyors and fans. Their adaptability ensures that they can meet the specific demands of various types of machinery.

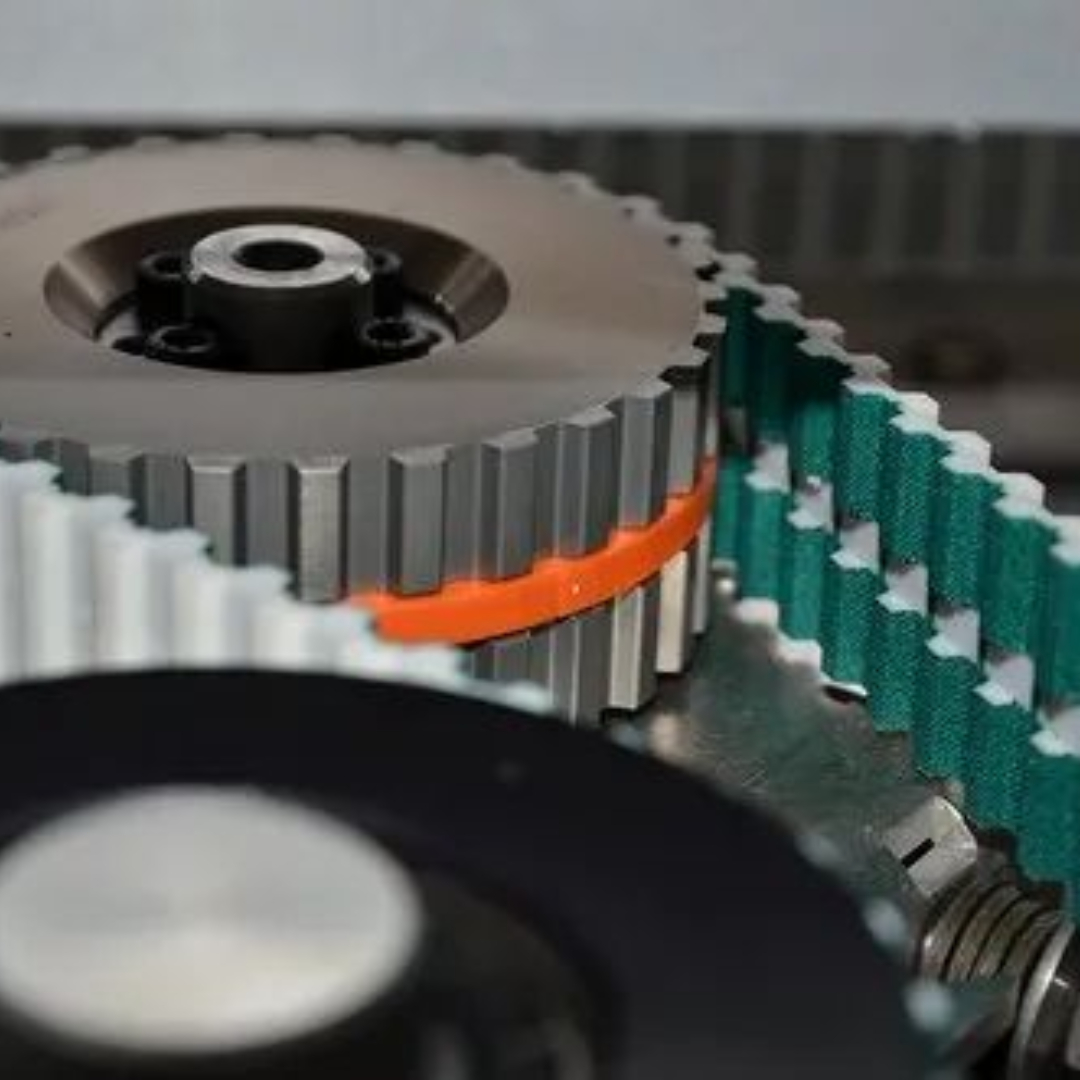

5. Energy Efficiency and Performance

Another key advantage of industrial Vee belts is their energy efficiency. The V-shaped profile increases surface contact with the pulleys, reducing energy loss through slippage and enhancing power transmission. This efficiency can lead to energy savings over time, especially in large-scale industrial operations where energy consumption is a critical factor.

Industries like HVAC, where systems run continuously, benefit greatly from the energy savings provided by Vee belts. Their ability to perform efficiently over long periods with minimal energy loss makes them a sustainable choice for businesses looking to optimize operational costs.

6. Smooth and Quiet Operation

Industrial Vee belts operate with minimal noise and vibration, making them ideal for applications where smooth operation is required. In comparison to chain drives or gear systems, which can be noisy and require more maintenance, Vee belts provide a quieter, more reliable solution.

For precision manufacturing, where machinery must operate with minimal disruption, the smooth and silent operation of Vee belts helps maintain a controlled and efficient environment, ensuring that production runs uninterrupted.

Conclusion: EHRE Belting’s Industrial Vee Belts for Optimal Power Transmission

At EHRE Belting, we understand the importance of reliable, durable, and efficient power transmission solutions. Our range of industrial Vee belts is designed to meet the needs of various industries, ensuring optimal performance and minimal downtime. With our Vee belts, you get a cost-effective, low-maintenance solution that delivers the power your machinery needs to perform at its best.

Ready to enhance your machinery’s performance? Contact EHRE Belting today to learn more about our industrial Vee belts and how they can improve your operations.