In industries that rely heavily on machinery, the choice of power transmission systems can significantly impact operational efficiency and performance. One such vital component is the industrial poly ribbed belt, also known as a multi-rib belt or serpentine belt. These belts have become an integral part of industrial systems due to their unique combination of flexibility, power transmission capability, and durability. In this post, we’ll explore the key advantages and applications of poly ribbed belts and why they are essential for industries that demand high efficiency and reliability.

1. Superior Power Transmission Capacity

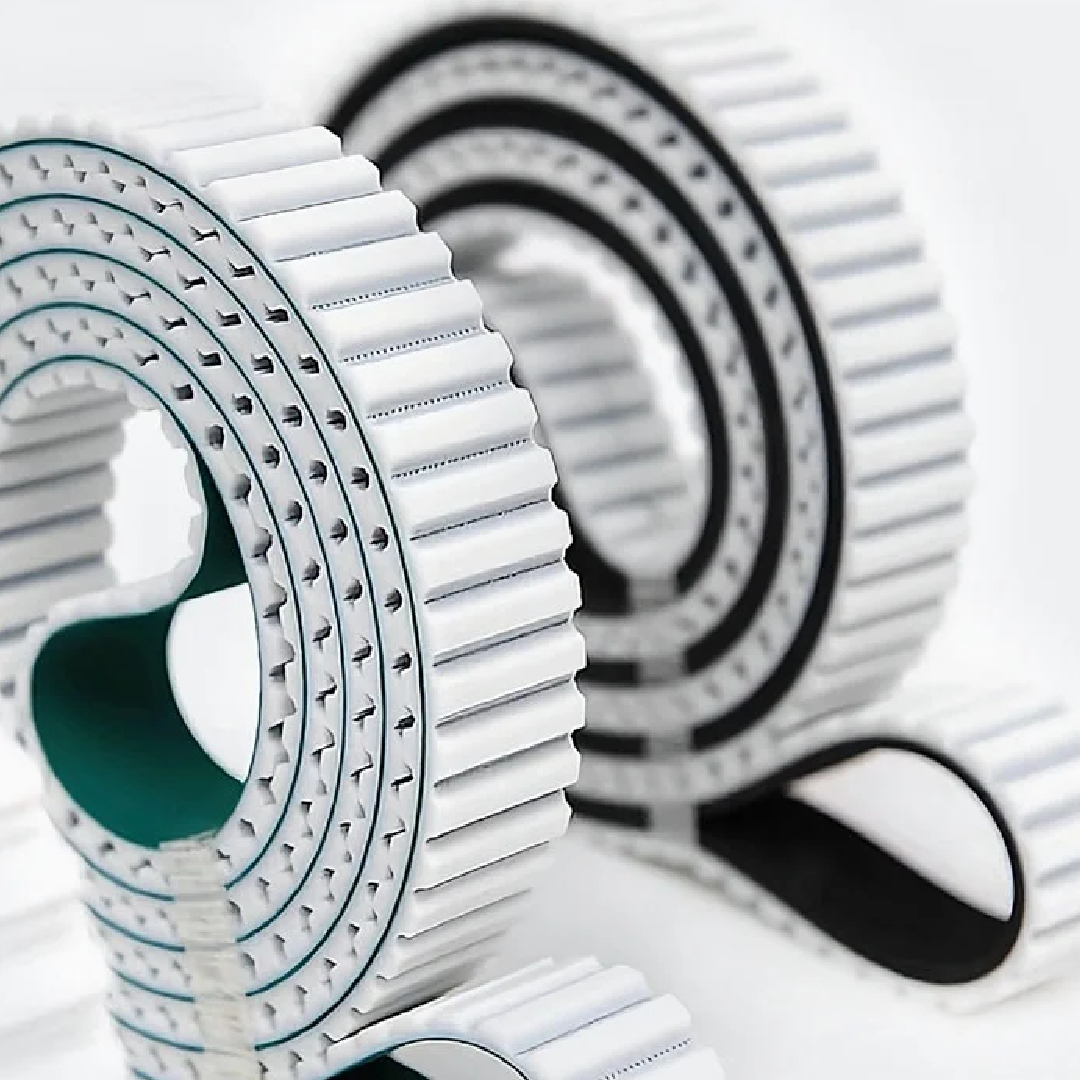

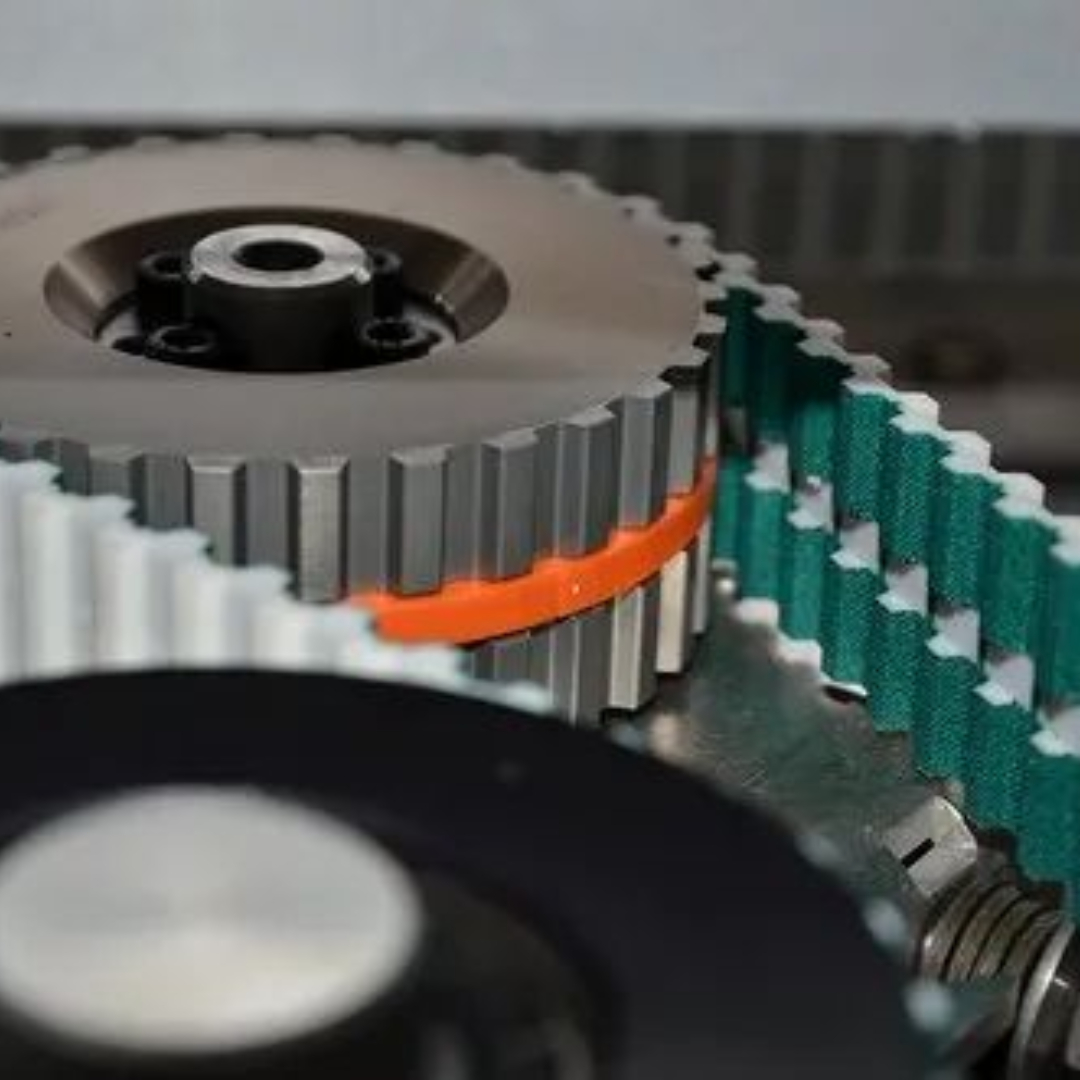

Industrial poly ribbed belts are designed with multiple longitudinal ribs on the belt’s surface, which allow them to provide excellent power transmission capabilities. The design creates more surface contact between the belt and the pulley, which significantly improves the belt’s ability to transmit higher loads with minimal slippage.

In industries like manufacturing, agriculture, and construction, where heavy-duty machinery is a cornerstone of operations, poly ribbed belts are essential for transmitting power efficiently across multiple components without the need for complex setups or numerous belts. Their ability to handle high loads makes them ideal for applications requiring strong and consistent power delivery.

2. Compact and Versatile Design

One of the standout features of poly ribbed belts is their compact design. Unlike traditional V-belts, which often require multiple belts to handle higher loads, a single poly ribbed belt can manage the same level of power transmission. This not only simplifies the belt configuration but also saves space within machinery.

For equipment manufacturers aiming to design compact and space-efficient machinery, poly ribbed belts are the perfect solution. Their ability to perform effectively within tight spaces without compromising on power transmission is highly beneficial for modern industrial systems that prioritize minimalism and efficiency.

3. Reduced Slippage and Improved Grip

Thanks to the multi-ribbed surface, industrial poly ribbed belts offer superior grip on pulleys, reducing the risk of slippage even under high-torque conditions. The ribbed structure increases the friction between the belt and pulley, ensuring that the belt stays firmly in place and performs reliably in demanding environments.

This feature is crucial for applications where consistent power delivery is needed, such as in conveyor systems, pumps, and fans. By minimizing slippage, poly ribbed belts help maintain smooth, continuous operation, reducing downtime and improving overall equipment efficiency.

4. Low Maintenance and Long Service Life

Industrial poly ribbed belts are known for their durability and low maintenance requirements. Made from high-quality rubber and other synthetic materials, these belts are resistant to heat, oil, and wear, making them ideal for harsh operating conditions. Their long service life reduces the need for frequent replacements and minimizes maintenance costs.

In industries where equipment runs continuously—like food processing, textiles, or packaging—poly ribbed belts help ensure that machinery operates without interruption. Their durability allows companies to focus on productivity rather than maintenance schedules.

5. Quiet and Smooth Operation

Another major benefit of poly ribbed belts is their ability to run smoothly and quietly. The belt’s flexible and ribbed design allows for better shock absorption and reduces vibration during operation. This is particularly important in industries where minimizing noise is essential, such as HVAC systems and precision equipment manufacturing.

For industries that prioritize creating a quieter working environment, poly ribbed belts offer the advantage of silent and efficient operation, enhancing both machinery performance and workplace comfort.

6. Versatility Across Industries

Poly ribbed belts are highly versatile and can be used in a wide range of applications across various industries. Whether it’s driving multiple accessories in an engine, transferring power to various components in an industrial setting, or maintaining consistent operation in heavy-duty machinery, poly ribbed belts are adaptable and reliable.

From automotive systems to agriculture and factory automation, the versatility of poly ribbed belts makes them a critical component in any system where dependable power transmission is required.

Conclusion: EHRE Belting’s Industrial Poly Ribbed Belts for Maximum Efficiency

At EHRE Belting, we offer high-performance industrial poly ribbed belts designed for efficiency, durability, and reliability. Our belts are engineered to provide superior power transmission with minimal slippage, ensuring that your machinery runs smoothly and efficiently.

Whether you need a solution for heavy-duty equipment or a compact system that demands consistent power delivery, EHRE Belting’s poly ribbed belts are the perfect fit. Contact us today to learn more about how our products can enhance your industrial operations and maximize your efficiency.