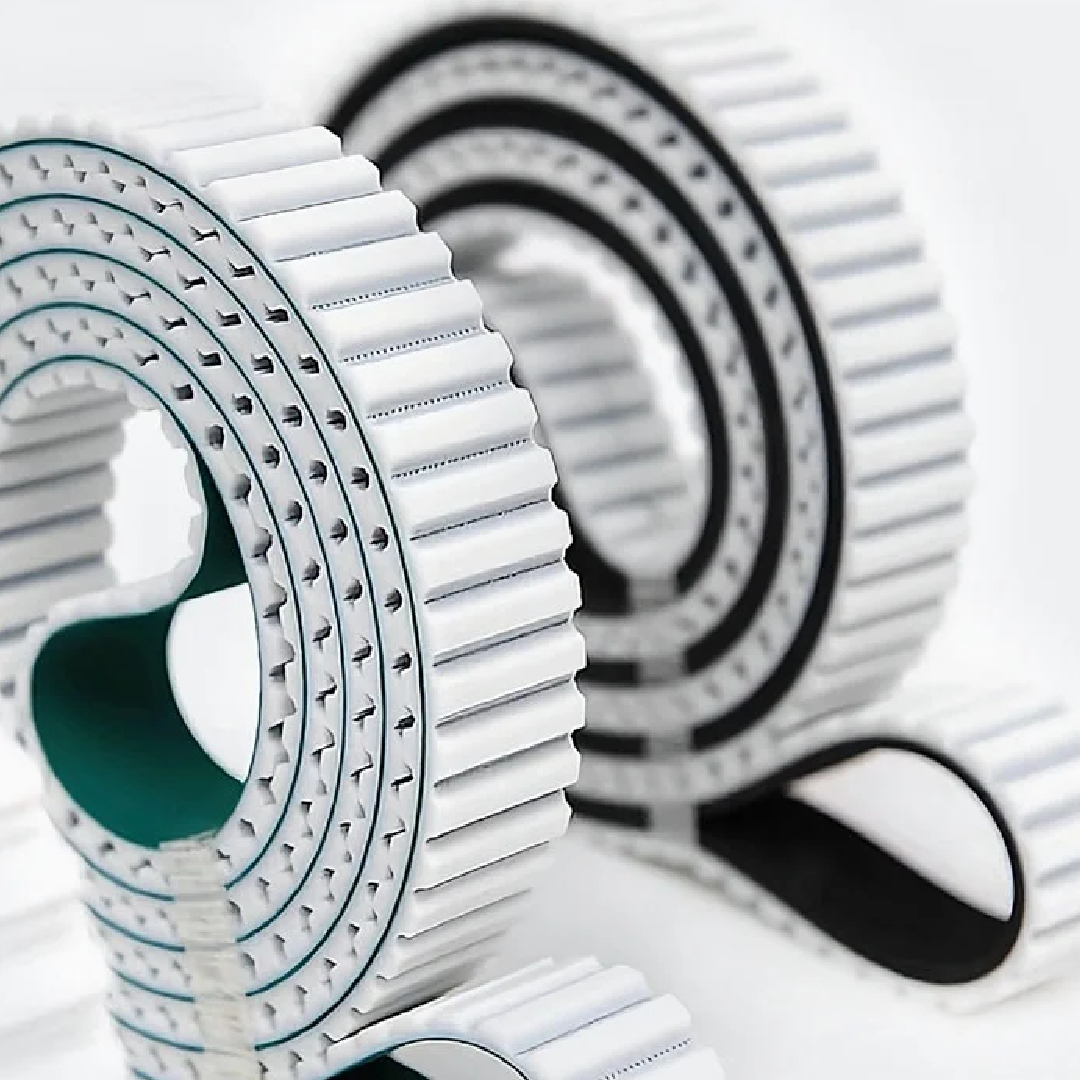

In industrial applications where precision, strength, and durability are paramount, PU timing belts (polyurethane timing belts) have become a go-to solution. These belts offer superior performance, longevity, and versatility, making them ideal for a range of industries, from automation and packaging to food processing and material handling.

In this post, we’ll explore the key advantages of PU timing belts, their applications, and why they’re an excellent choice for industries seeking efficient and reliable power transmission solutions.

1. Superior Durability and Resistance

PU timing belts are renowned for their durability. Constructed from high-quality polyurethane materials, these belts provide excellent resistance to wear, abrasion, and tearing. Unlike rubber belts, PU timing belts can withstand extreme temperatures, exposure to oils, chemicals, and other harsh environmental factors without degrading.

In industries like food processing, chemical manufacturing, and pharmaceuticals, where belts are frequently exposed to corrosive substances, PU timing belts offer a long-lasting solution. Their ability to maintain performance in challenging environments reduces the need for frequent replacements, thereby lowering maintenance costs and downtime.

2. Precision Performance and Synchronization

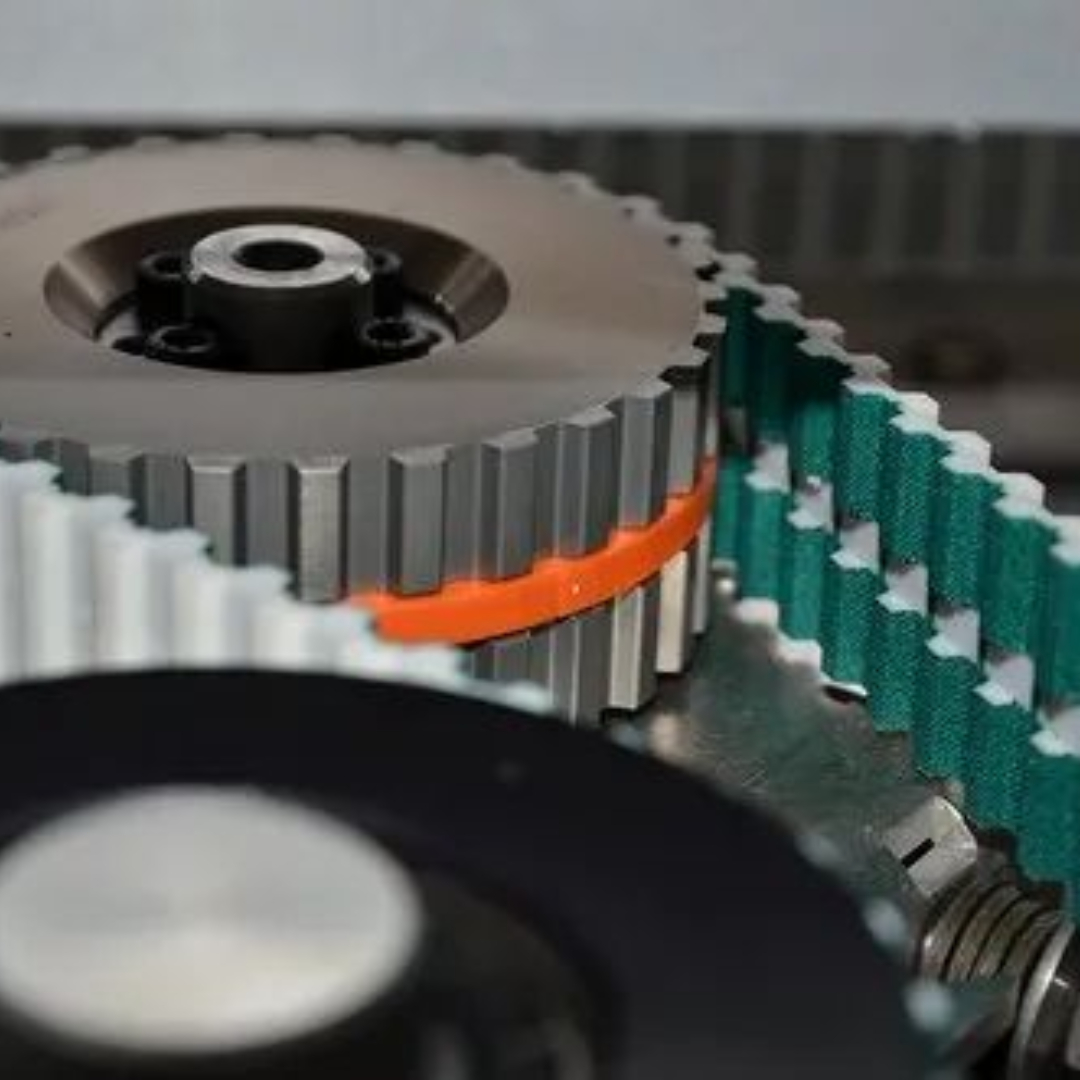

One of the standout features of PU timing belts is their ability to provide highly accurate synchronization between mechanical components. The precise tooth profile of these belts ensures smooth and reliable power transmission, making them ideal for applications where timing and accuracy are critical.

For industries such as automation, robotics, and CNC machinery, where precision is non-negotiable, PU timing belts ensure that all components move in perfect unison. This helps avoid costly errors, enhances product quality, and improves the overall efficiency of the system.

3. Versatility Across a Range of Applications

PU timing belts are highly versatile, designed to meet the needs of a wide variety of industries. Whether you need a belt for light-duty applications or heavy-load machinery, PU timing belts can be customized to suit specific operational requirements. They are commonly used in conveyors, material handling systems, packaging machines, and textile equipment.

Their adaptability makes them an excellent choice for businesses seeking a reliable, efficient solution across multiple applications. In automated systems or production lines, PU timing belts provide smooth, continuous operation, ensuring minimal disruptions in workflow.

4. High Tensile Strength for Heavy Loads

One of the key advantages of PU timing belts is their exceptional tensile strength. The combination of polyurethane and steel or Kevlar cords provides excellent resistance to stretching, allowing PU belts to handle higher loads without losing their shape or performance. This feature is particularly beneficial in industries requiring heavy-duty machinery, such as construction, automotive manufacturing, and mining.

By maintaining their form under heavy loads, PU timing belts ensure consistent and efficient power transmission, preventing the risks of slippage, misalignment, or belt failure, which can lead to costly downtime and repairs.

5. Low Noise and Smooth Operation

In addition to their strength and durability, PU timing belts are known for their quiet and smooth operation. This makes them an ideal choice for applications where noise reduction is important, such as in medical devices, HVAC systems, or precision manufacturing. The low noise output enhances the overall working environment, reduces mechanical stress, and minimizes wear on other components.

For businesses looking to reduce operational noise while maintaining high efficiency, PU timing belts are an excellent solution that balances both performance and comfort.

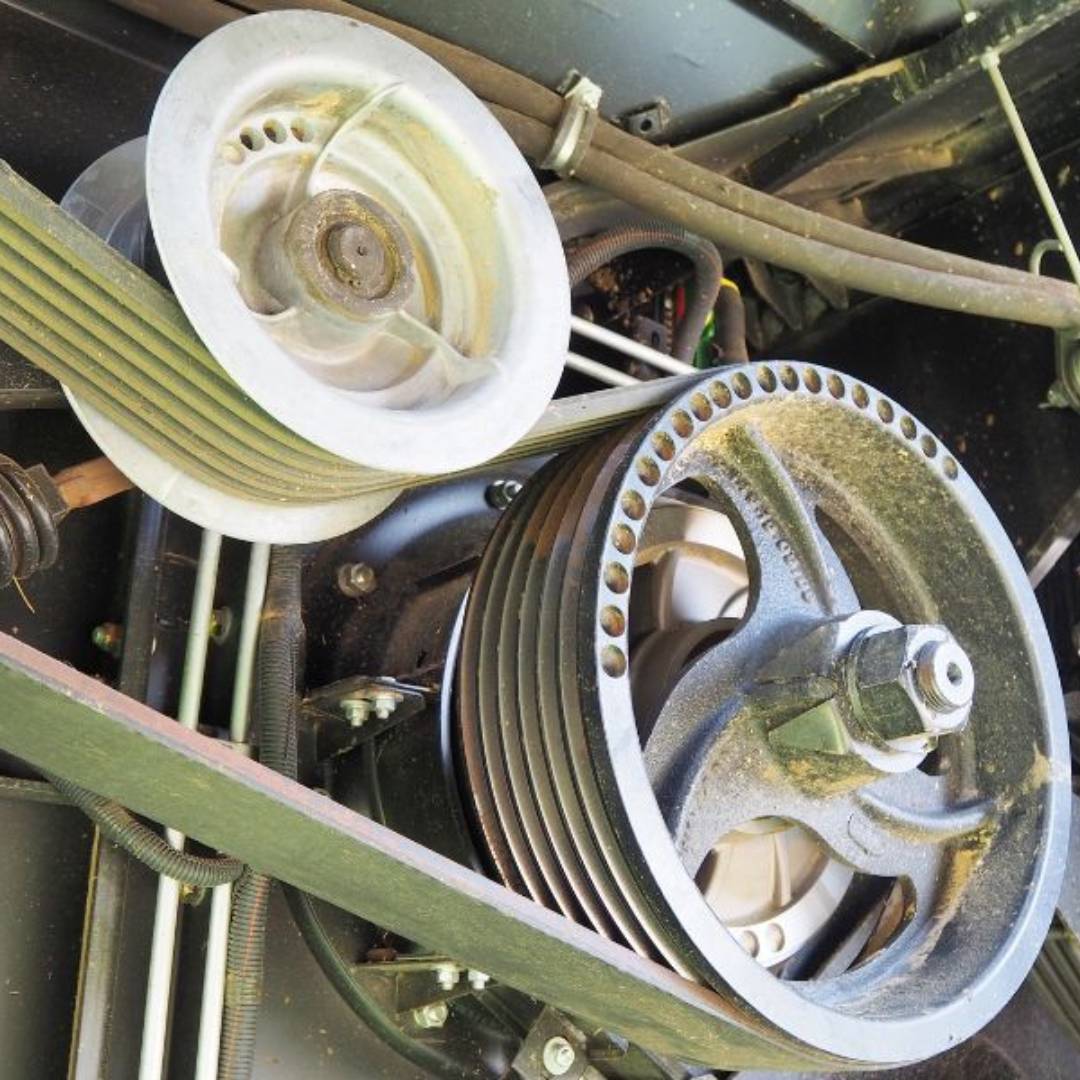

6. Minimal Maintenance and Long Service Life

PU timing belts are designed for longevity and minimal maintenance. Their resistance to wear and environmental stressors means they require less frequent inspection or replacement compared to traditional rubber belts. With proper tensioning and alignment, PU timing belts can run for extended periods without losing their efficiency.

For industries that operate 24/7, like food production or logistics, this low-maintenance feature translates into reduced downtime and lower overall operational costs. The long service life of PU belts makes them a cost-effective investment for any business looking to optimize their machinery’s performance.

Conclusion: EHRE Belting’s PU Timing Belts for Reliable Power Transmission

At EHRE Belting, we provide high-quality PU timing belts that are designed for durability, precision, and versatility. Whether you need belts for automation, food processing, or heavy-duty machinery, our PU timing belts deliver the performance you need to keep your operations running smoothly.

If you’re looking for reliable and durable power transmission solutions, contact us today to find out how EHRE Belting’s PU timing belts can meet your industrial needs.