In industries where precision and accuracy are paramount, the role of timing belts is crucial. Among the most versatile of these belts are special profile timing belts, designed for unique and highly specialized applications. These belts differ from standard timing belts in that they can be customized with different profiles, materials, and coatings to meet specific operational needs.

In this post, we’ll explore the benefits of special profile timing belts and how they enhance performance in industries where precise synchronization and customization are critical.

1. Customized for Unique Industrial Needs

Special profile timing belts are tailored to meet the exact requirements of specific machinery. Unlike standard timing belts, which have fixed tooth profiles, special profile timing belts can be designed with unique tooth shapes, materials, or sizes to ensure optimal performance in specialized environments.

For industries such as packaging, printing, and pharmaceuticals, where machines must operate with pinpoint accuracy, custom profiles ensure that the belts mesh perfectly with the corresponding pulleys. This customization reduces slippage, increases efficiency, and minimizes wear and tear on both the belt and machine components.

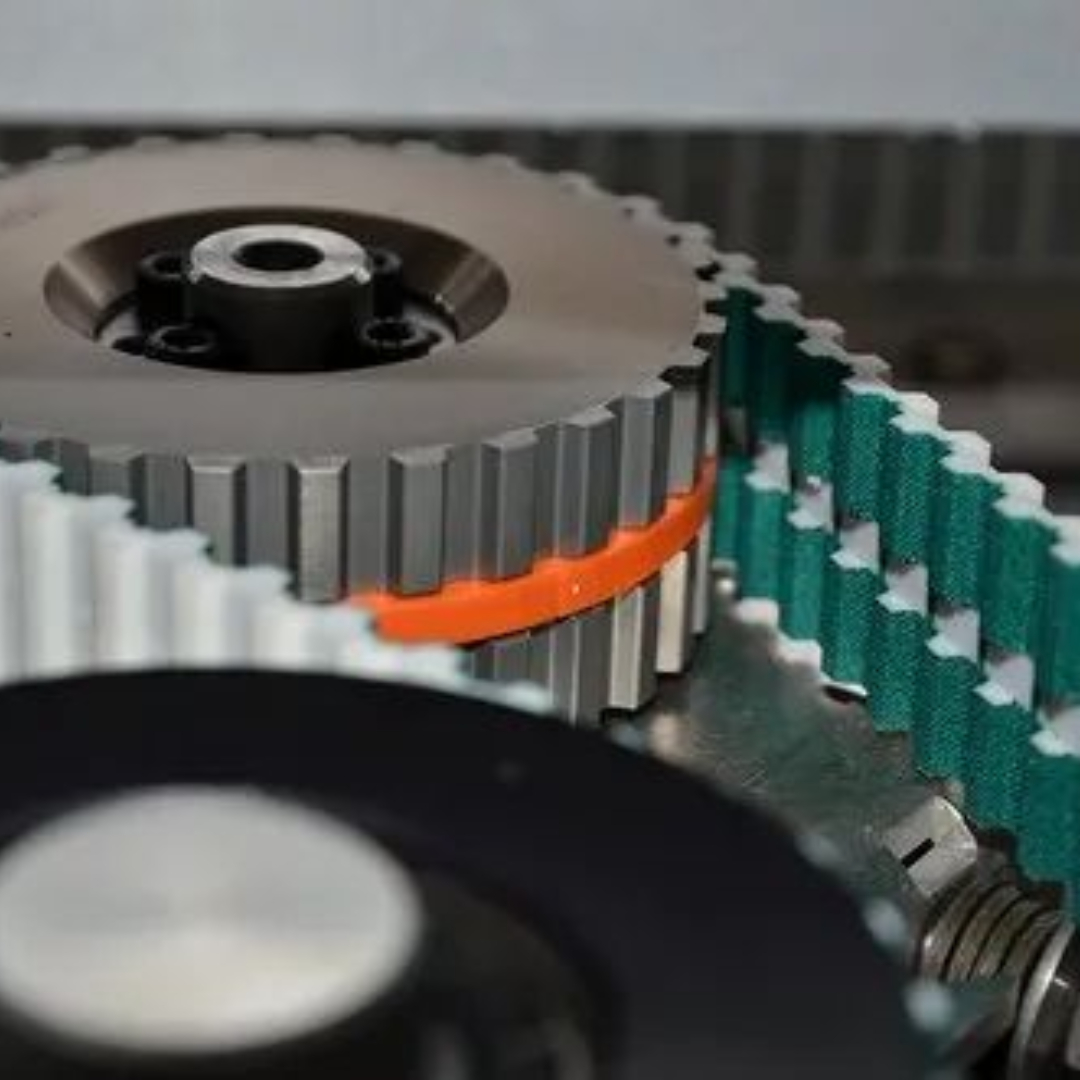

2. Precision Synchronization for Accurate Operation

The core function of any timing belt is to provide precise synchronization between two or more components, ensuring they move in perfect harmony. Special profile timing belts take this precision to the next level by offering enhanced grip and smoother movement, even under high-stress conditions.

For example, in robotics or automated manufacturing, where timing and accuracy are critical, special profile timing belts allow for reliable and repeatable motion control. This precision is essential for preventing costly errors, improving production quality, and maintaining the smooth operation of automated systems.

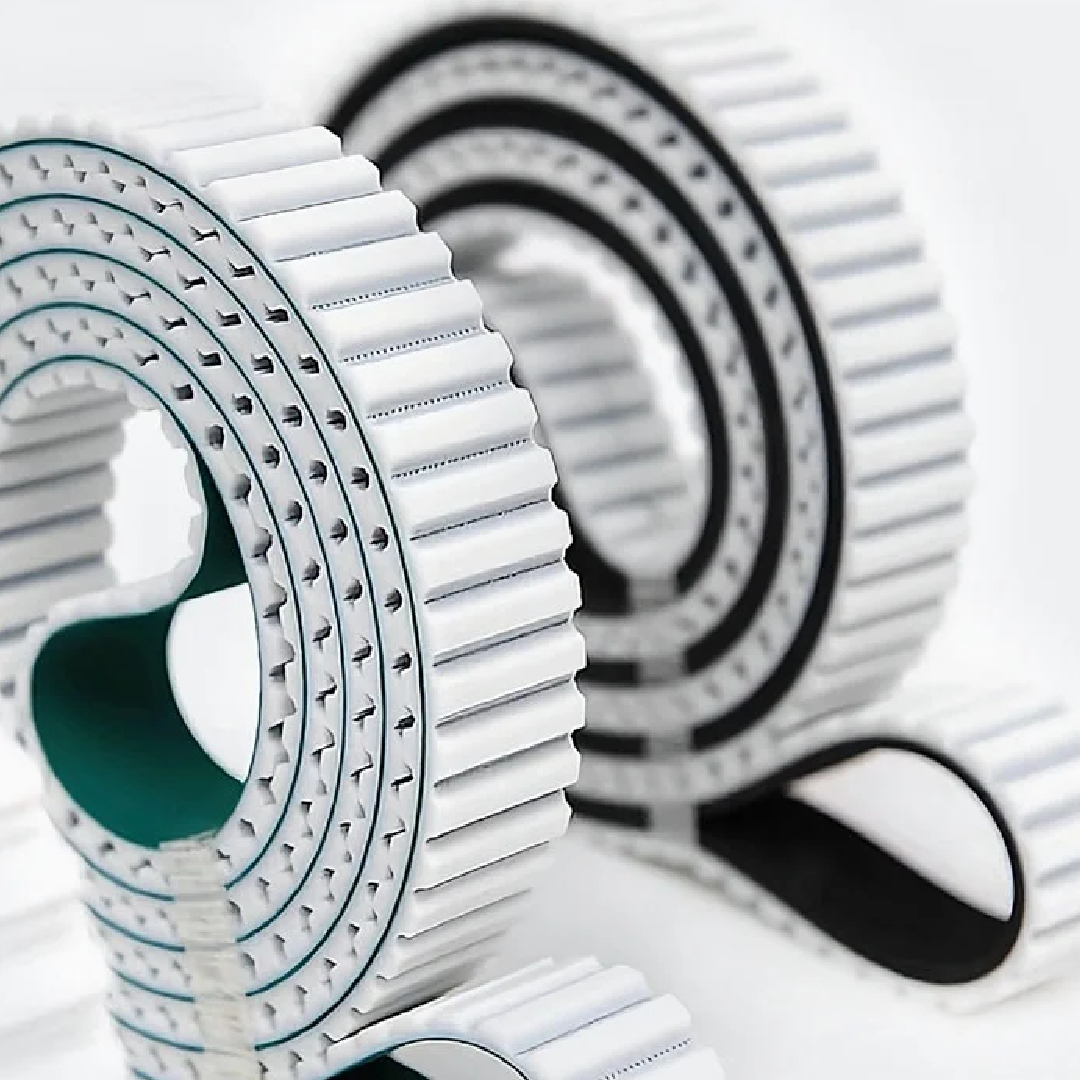

3. High Durability and Resistance to Environmental Factors

Special profile timing belts are often constructed from high-quality materials such as rubber, polyurethane (PU), or other synthetic materials that offer exceptional resistance to environmental stressors like heat, chemicals, and abrasion. These materials are chosen based on the specific needs of the application.

In industries such as food processing or chemical manufacturing, where belts are exposed to harsh conditions, special profile timing belts offer the durability needed to perform reliably. They resist stretching and cracking, ensuring a longer service life, reducing the need for frequent replacements, and lowering maintenance costs.

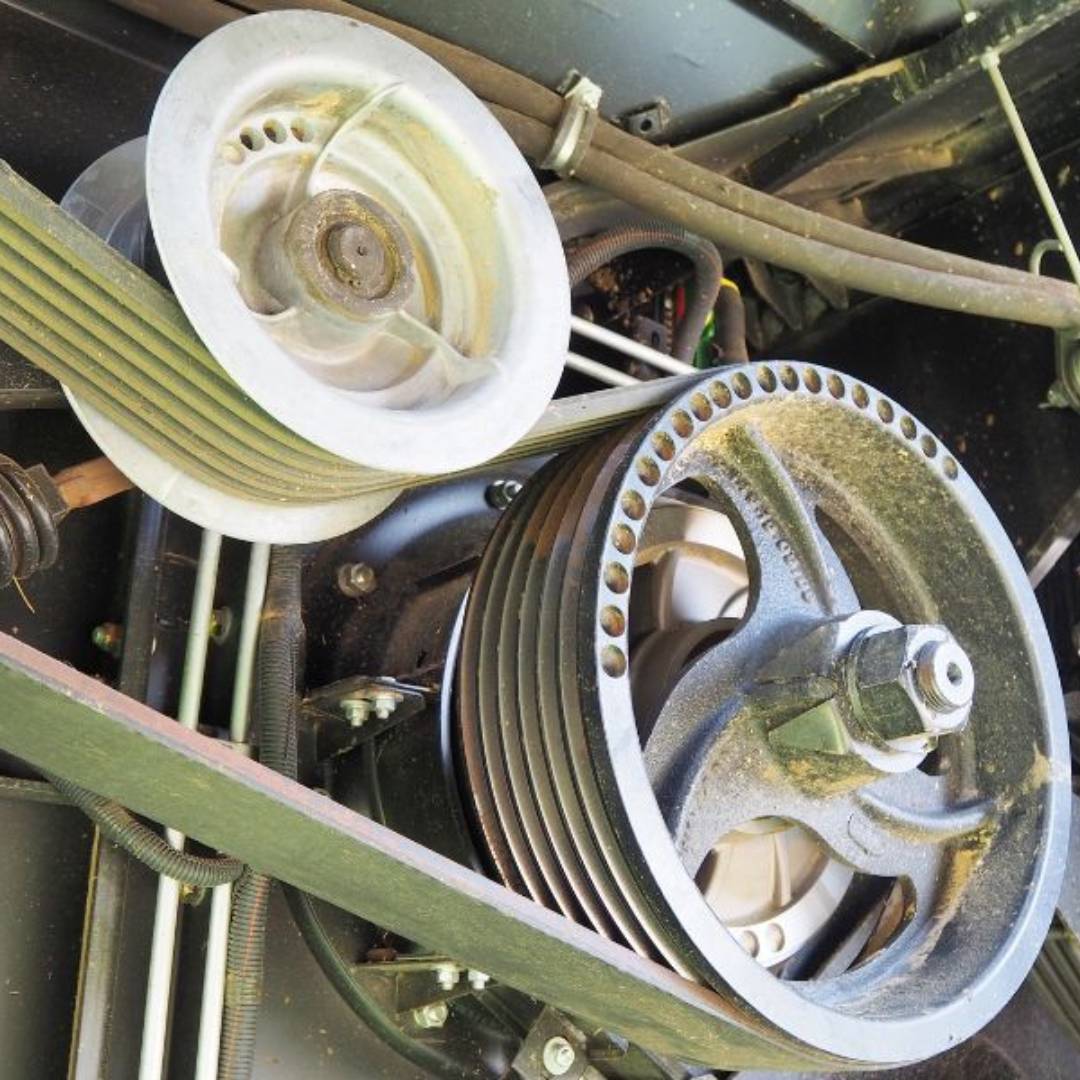

4. Enhanced Load Handling and Performance

One of the significant advantages of special profile timing belts is their ability to handle higher loads and maintain accurate timing under stress. The customized profiles allow for better distribution of load across the teeth, reducing the risk of belt deformation or failure.

For applications involving heavy-duty machinery, such as conveyors or industrial automation, special profile timing belts ensure consistent performance, even under high loads or speeds. The belts are designed to maintain accurate timing, preventing operational issues that could lead to costly downtime or damage to equipment.

5. Low Maintenance and Long Service Life

Special profile timing belts are designed with longevity in mind. The materials used and the precision design mean these belts require minimal maintenance. When properly installed and aligned, special profile timing belts can run for extended periods without the need for frequent adjustments or replacements.

This long service life is a key advantage in industries where downtime needs to be minimized. Regular maintenance checks can ensure the belt is operating smoothly, but overall, these belts offer a set-and-forget reliability that reduces operational interruptions.

6. Versatile Application Across Specialized Industries

While special profile timing belts are designed for specific tasks, they are incredibly versatile across a range of industries. Whether it’s driving precise movements in 3D printers, powering medical equipment, or ensuring accurate positioning in CNC machines, these belts play a vital role in ensuring the smooth and synchronized operation of specialized machinery.

Their ability to be customized means that no matter the complexity or specificity of the task, there’s a special profile timing belt that can be tailored to meet those requirements.

Conclusion: EHRE Belting’s Special Profile Timing Belts for Customized Precision

At EHRE Belting, we understand that one size does not fit all when it comes to timing belts. That’s why we offer a wide range of special profile timing belts that can be customized to meet the exact specifications of your machinery. Our belts are designed to offer superior synchronization, durability, and performance in even the most demanding environments.

If you’re looking for a solution that offers precision, reliability, and long-lasting performance, contact us today to learn more about how our special profile timing belts can help optimize your operations.