In today’s fast-paced industrial landscape, maintaining efficiency and reliability in machinery is crucial. Industrial rubber timing belts have become the backbone of various manufacturing sectors due to their ability to deliver precision, durability, and cost-efficiency. This blog explores why these belts are essential for businesses that depend on seamless power transmission in modern manufacturing.

1. Precision in Motion

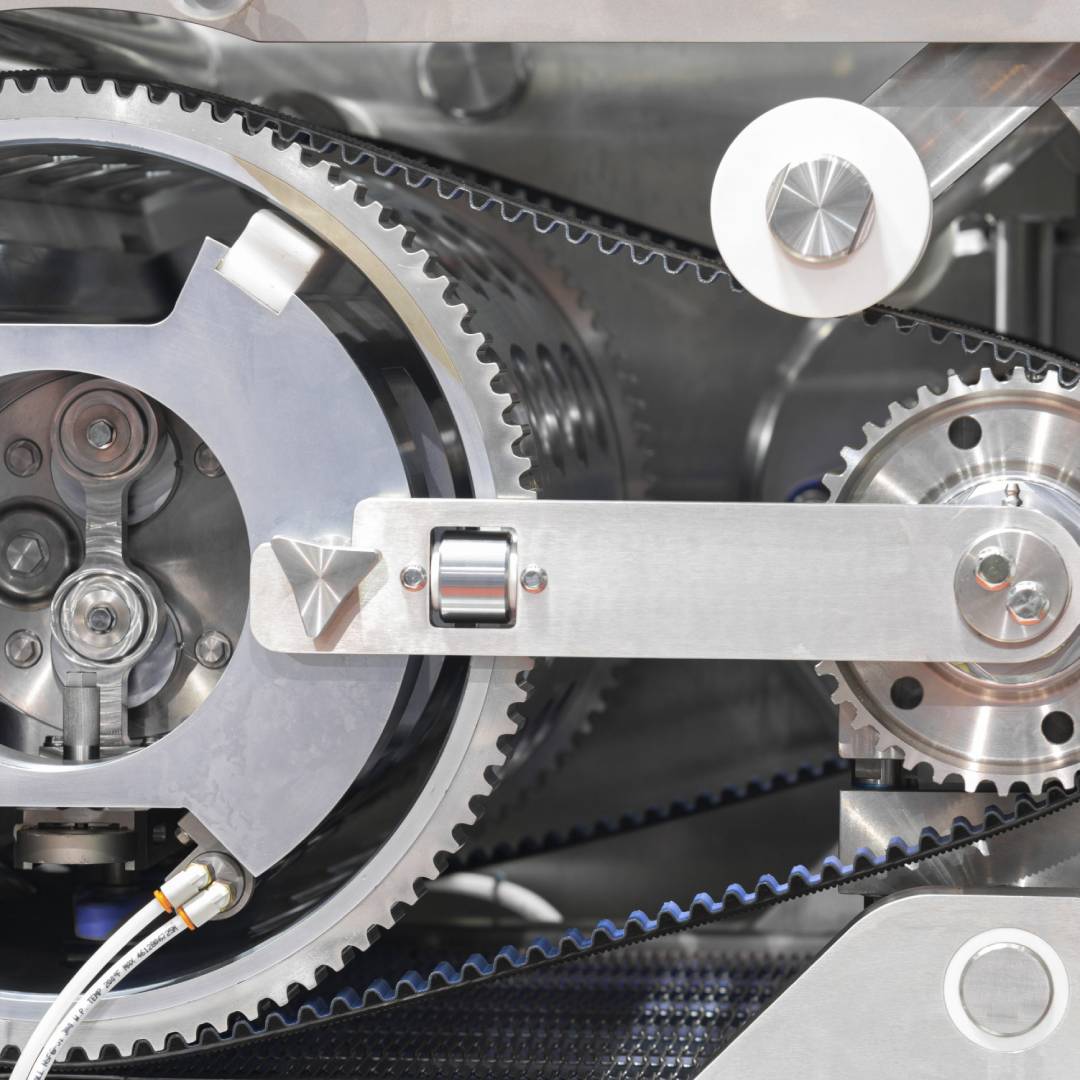

One of the most significant advantages of industrial rubber timing belts is their precision. These belts are designed to maintain exact synchronization between rotating components, ensuring that machinery functions at peak performance. Unlike chains or gears, which can stretch or wear over time, rubber timing belts maintain their accuracy, providing a more reliable solution for industries where even a slight deviation in timing can cause production errors.

In industries like automotive manufacturing or electronics assembly, precision is everything. A single misalignment can lead to production defects, wasted materials, and costly downtime. By incorporating industrial rubber timing belts, manufacturers can safeguard their operations against such risks and maintain the high standards their clients expect.

2. Durability and Longevity

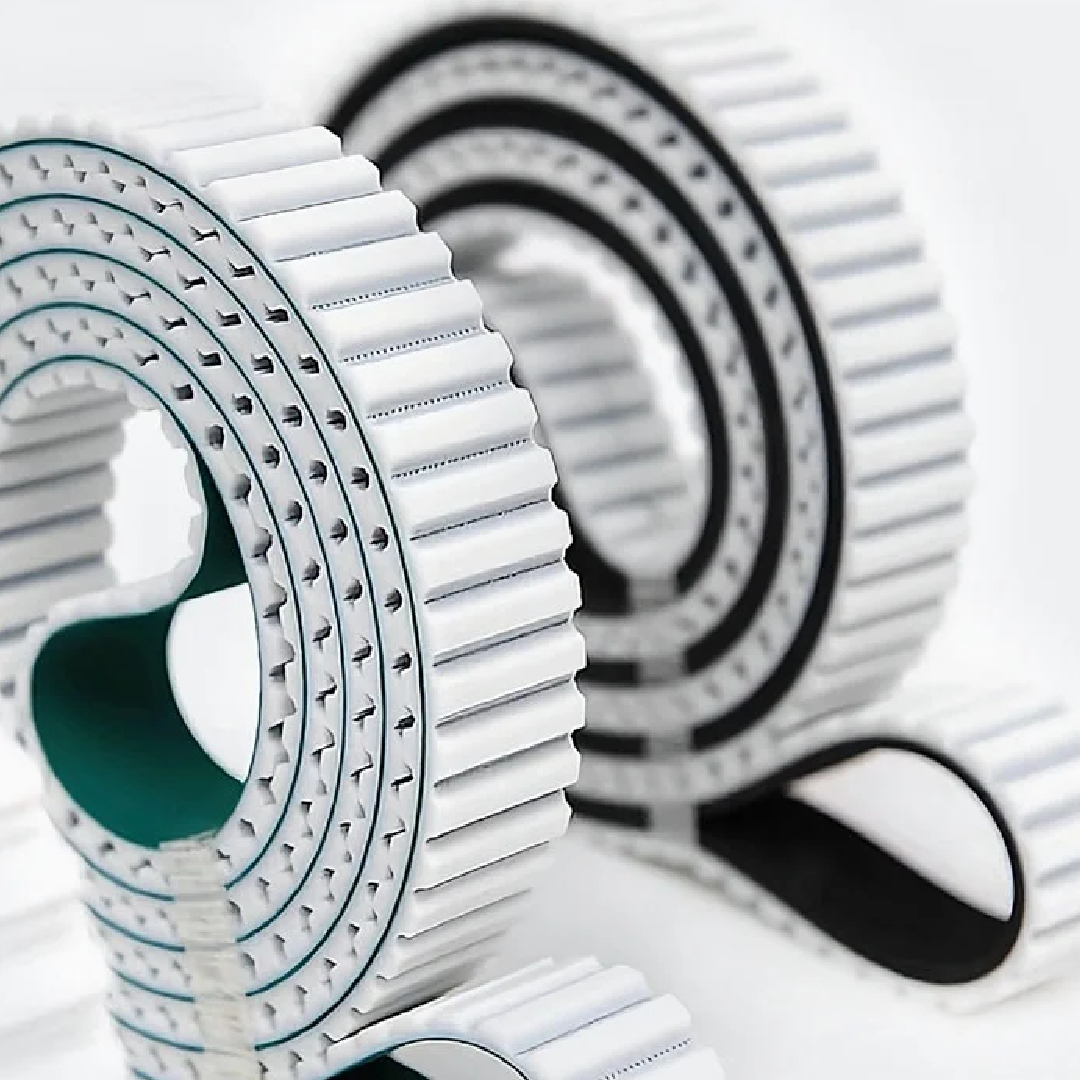

Industrial environments can be harsh, with machinery constantly exposed to high temperatures, oil, moisture, and other wear-inducing factors. Rubber timing belts are specially designed to withstand these challenges. Made from high-quality, heat-resistant rubber, these belts resist stretching, cracking, and wear over time, ensuring longevity and reducing the frequency of replacements.

For industries like food processing or packaging, where equipment runs continuously, durable timing belts minimize downtime and maintenance costs. They ensure that operations run smoothly without frequent interruptions, which can have a ripple effect on production schedules and delivery timelines.

3. Cost-Effectiveness and Maintenance Advantages

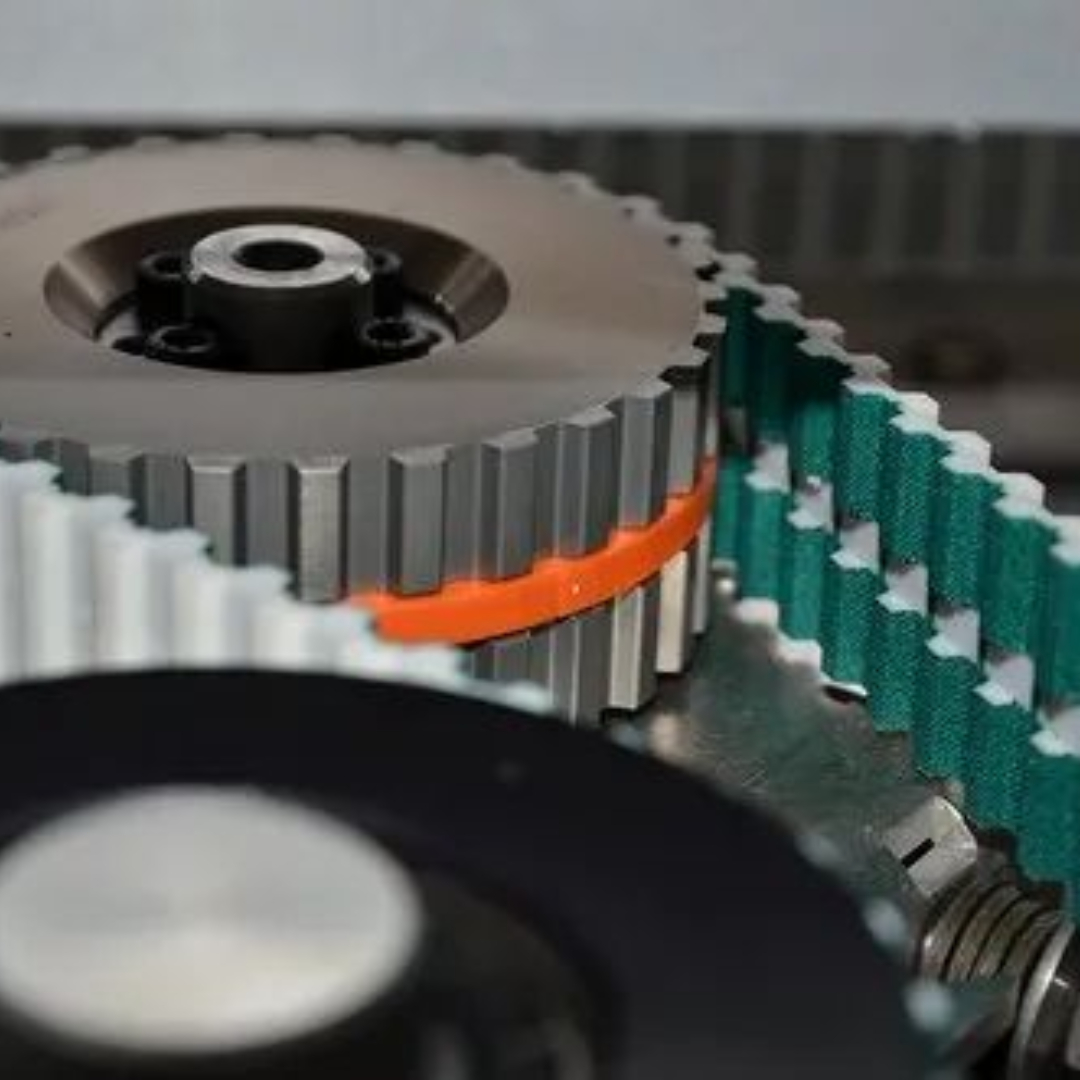

Compared to alternative power transmission systems like chains or gears, industrial rubber timing belts offer significant cost advantages. They don’t require lubrication, reducing the overall maintenance requirements and operational costs. Additionally, the smooth operation of these belts minimizes energy losses due to friction, making them more energy-efficient over time.

Consider a pharmaceutical manufacturer with dozens of machines operating simultaneously frequent maintenance or breakdowns can halt the production process entirely. Rubber timing belts eliminate the need for regular lubrication and adjustments, meaning reduced downtime and lower long-term operational costs.

4. Versatility Across Industries

Industrial rubber timing belts are incredibly versatile, finding applications in a wide range of industries, from automotive to textile and aerospace. They are adaptable to various sizes and configurations of machinery, making them an ideal solution for manufacturers looking to streamline their operations. Whether it’s driving conveyor belts or ensuring precise movement in robotic arms, timing belts play an essential role in industrial automation.

For businesses in regions like the Midwest’s manufacturing hubs or Southeast’s automotive sector, where industrial efficiency is critical, having reliable and adaptable transmission systems like rubber timing belts can make all the difference.

5. Environmentally Friendly Option

Rubber timing belts not only provide operational efficiency but are also an eco-friendly option. Their long service life reduces the frequency of replacements, minimizing waste. Additionally, their ability to operate without lubrication prevents the use of harmful oils that can contaminate the environment.

For companies prioritizing sustainability, especially in green manufacturing sectors, rubber timing belts are a reliable choice that supports eco-conscious operations.

Conclusion: Why EHRE Belting’s Industrial Rubber Timing Belts Are the Right Choice

At EHRE Belting, we specialize in high-quality industrial rubber timing belts designed to meet the demanding needs of modern manufacturing. Our belts offer precision, durability, and versatility across multiple industries, helping you minimize downtime and optimize productivity.

If you’re looking to improve your production efficiency and reduce operational costs, contact us today to discuss how our industrial rubber timing belts can enhance your machinery’s performance. Get in touch for a customized solution that fits your specific industrial requirements.